What are the Uses and

Working Principles of Industrial Relays?

In modern industrial automation, industrial relays play a vital role as they are the key component that connects the control system to the actuator. In this article, we will briefly introduce you to the basic concepts, advantages, applications and working principles of industrial relays.

What is an industrial relay?

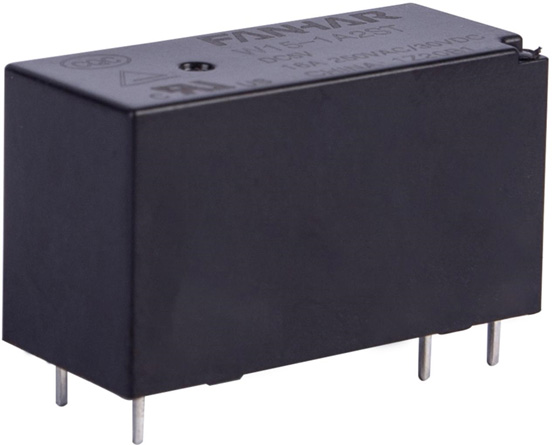

An industrial relay is an electrical control device used to switch and control electrical signals in a circuit. It achieves control of one circuit by controlling one or more switches in another circuit (usually low voltage to control high voltage). Industrial relays usually consist of an electromagnetic coil, contacts, and a housing. When the electromagnetic coil is energised, it generates a magnetic field that causes the contacts to close or break, automatically switching (ON/OFF) the state of the circuit.

Advantages of industrial relays

1.

High sensitivity and low control power: Industrial relays, especially solid state relays, have a wide input voltage range, low drive power, and are compatible with most logic integrated circuits, eliminating the need for additional buffers or drivers.

2. High life and reliability: With no mechanical parts, industrial relays can operate in high shock and vibration environments, have solid state devices to fulfil contact functions, and are therefore long-lasting and reliable.

3. Fast switching: Solid state relays use solid state devices, switching speed can be from a few milliseconds to a few microseconds, fast response time.

4. Small electromagnetic interference: there is no input ‘coil’, no contact arc and jump back, thus reducing electromagnetic interference.

5. Energy saving and environmental protection: through reasonable configuration and control, it can effectively reduce energy consumption and waste.

Application of industrial relays

Industrial relays play a vital role in industrial automation and are widely used in the following fields:

1. Motor Control: Relays play a key role in motor control, such as in starters and inverters.

2. Sensor control: Relays are used in sensor control such as proximity switches and photoelectric switches.

3. Safety control: safety relays are widely used in automation equipment and safety control systems such as emergency stops, safety gates and safety light curtains.

4. Power systems and industrial equipment: ground fault relays are used to detect ground faults in electrical systems and quickly cut off circuits when a ground fault occurs to ensure personal safety and normal operation of equipment.

Woking principle of industrial relays

The working principle of industrial relays is based on the electromagnetic effect. Electromagnetic relays are generally composed of an iron core, coil, armature, contact reeds and so on. When a certain voltage is added to both ends of the coil, a magnetic field is generated by the current flowing through the coil, and the armature is sucked to the iron core under the action of electromagnetic force, which drives the contacts to close or break, and realises the on-off control of the circuit.

The input signal of the relay increases continuously from zero to reach the action value when the armature starts to absorb, and the output signal of the relay immediately jumps from disconnection to closure, i.e., the normally open contact goes from disconnection to on. Once the contact is closed, the input quantity continues to increase, the output signal will no longer change. When the input quantity drops from a value larger than the action value to the release value, the relay starts to release, and the normally open contact breaks.