FH44L latching relay is a high-performance miniature control element designed for smart home, home appliance equipment and industrial automation. It has passed UL, TUV, CQC and other international certifications. With the core advantages of compact size (20.2×10×15.5mm), ultra-low power consumption (coil power consumption of only 250mW) and high reliability, it meets the multiple demands of modern electronic devices for energy saving, space optimization and harsh environmental adaptability.

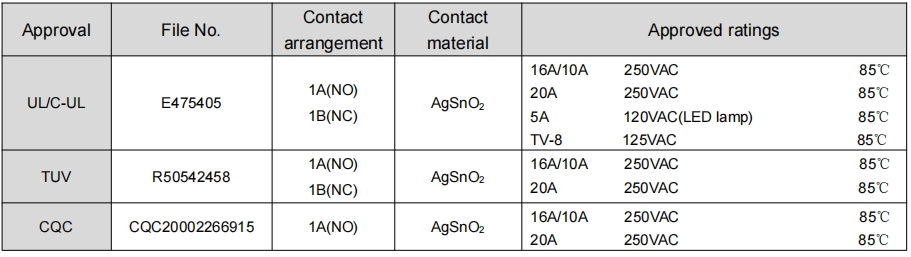

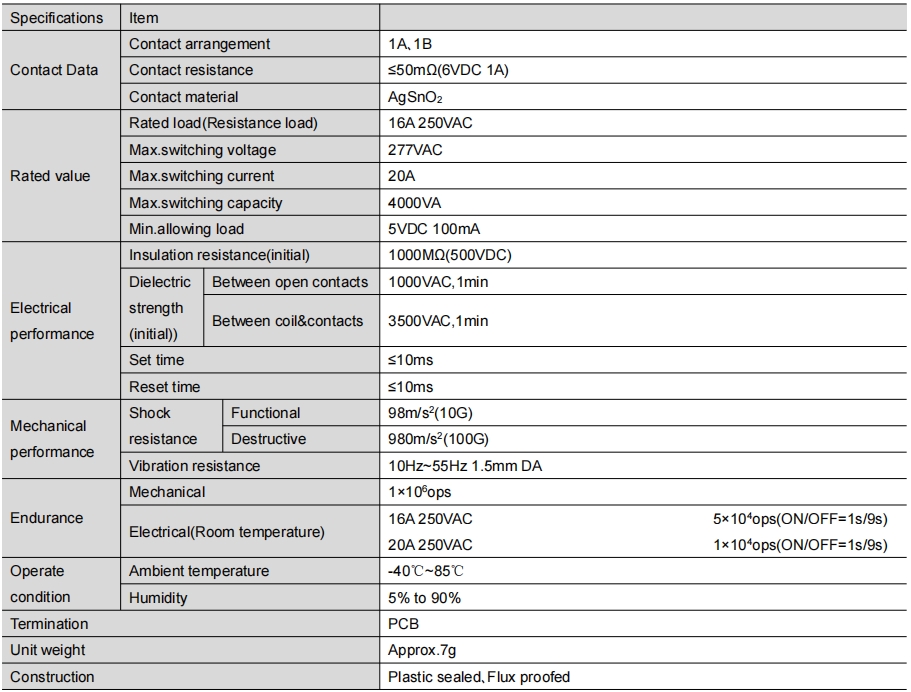

Elevated load capacity: Accommodates 16A/250VAC standard loads, with an instantaneous withstand current of up to 20A (10ms), appropriate for high-power applications involving frequent switching.

AgSnO₂ silver tin oxide contacts provide superior anti-arc and anti-melting welding capabilities, with an initial contact resistance of ≤ 50mΩ, hence providing prolonged stable conductivity.

Lifetime performance: Under 16A load, the electrical life reaches 50,000 times (ON/OFF=1s/9s); under 20A load, the life is 10,000 times to meet the needs of high-intensity use.

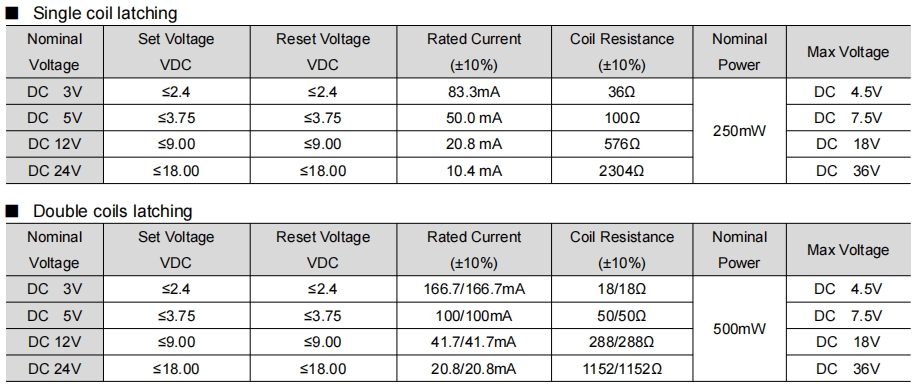

Single coil model: rated power 250mW (e.g. DC5V/50mA), suitable for battery powered devices;

Dual coil model: total power 500mW (e.g. DC5V dual coil, 100mA per coil), supports independent control logic.

Compact design: With a height of about 15.5mm, it represents the slimmest design in its category, ideal for embedded installation and high-density PCB configurations.

Available dual structure:

Flux Proofed: Appropriate for sterile environments (free from pollutants such as H₂S, dust, etc.) and offers superior cost-effectiveness;

Plastic Sealed: Higher level of protection and resistance to industrial environments containing corrosive gases or dust.

Diversified coil configurations: Supports single-coil (L1) and dual-coil (L2) latching modes; single coil switches state by pulse signal; dual coil supports independent “set/reset” control for more flexible logic.

Wide voltage adaptability: the rated voltage of the coil covers DC3V to 24V, meeting the needs of different power supply systems (such as low-voltage control for smart homes or high-voltage drive for industrial equipment).

Extreme temperature tolerance: Operating temperature range -40℃~85℃, adapting to outdoor equipment in cold areas or high temperature industrial cabinets.

Shock and vibration resistance:

Mechanical durability: 1×10⁶ mechanical operations without failure;

Shock resistance: operational capability under 980 m/s² (10G) shock;

Vibration resistance: consistent performance in a vibration environment ranging from 10Hz to 55Hz.

Electrical safety specifications: 3500VAC between contacts and coils, 1000VAC between open points, effectively isolating high and low voltage circuits; UL Class F insulation system to guarantee insulation stability at prolonged high temperatures.

Smart switches and sockets: manage lighting, air conditioning, and other devices using low-power single coils, enabling remote app or voice command operation.

Temperature control system: incorporated in an intelligent thermostat, rapid response to temperature fluctuations (≤10ms), accurate regulation of heating and cooling apparatus.

Kitchen appliances: high-current switching control for microwave and electric ovens; AgSnO₂ contacts exhibit resistance to frequent cycling and transient overloads.

Washer/dryer: motor drive and pump regulation, sealed design to inhibit water vapour and dust penetration.

Sensor Module: Stable signal switching in vibration environments, and shock-resistant performance to ensure the reliability of production line equipment.

Automation line: dual coil configuration to realize precise state locking and avoid false triggering, suitable for robotic arm and conveyor control.

Solar controller: Wide temperature range design for extreme outdoor climate, low power consumption to prolong the life of the energy storage system.

LED lighting system: support 5A/120VAC LED light load, suitable for commercial lighting intelligent dimming scenarios.

First time use reset: transportation vibration may lead to contact state abnormality, need to apply rated voltage pulse (width ≥ 50ms) to reset before energizing.

Prohibit double coils to be energized at the same time: double coils should be strictly time-shared to control the “set” and “reset” signals to avoid overheating and damage to the coils.

PCB layout specification: refer to the drawing for pin aperture and spacing (tolerance ±0.1mm) to ensure welding precision;

It is recommended to reserve space for heat dissipation to avoid heat accumulation in high temperature environment.

Maintenance recommendations: regular check of contact cleanliness, sealed products in complex environments need to be tested every 2 years for protection performance.