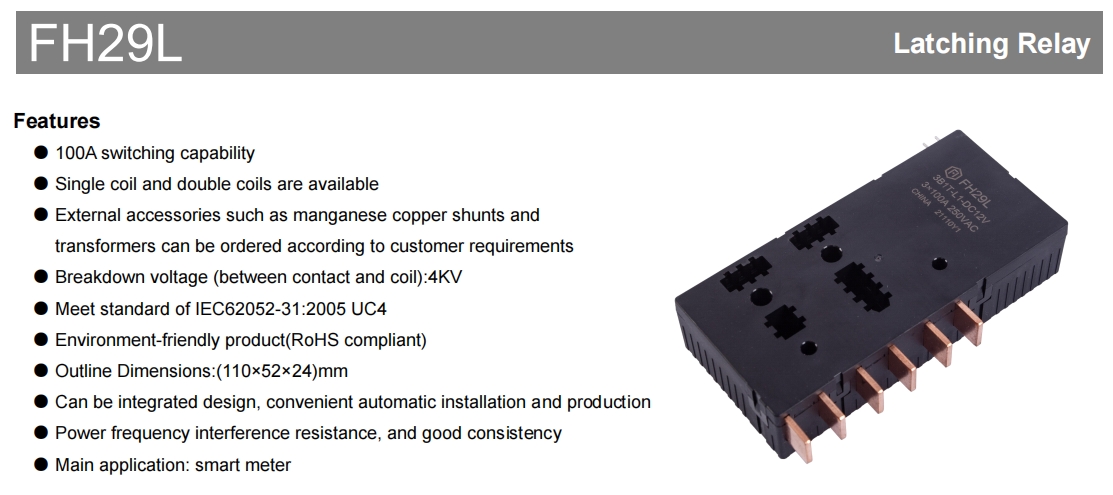

The FH29L is a high-performance latching relay developed by Fanhar and designed for smart meters and high-current control scenarios. With its 100A high current carrying capacity, flexible dual/single coil design, and strict compliance with international standards (IEC62052-31:2005 UC4), this product is ideal for industrial automation and energy management. At the same time, its environmental certification (RoHS) and compact structure (110 x 52 x 24 mm) further emphasize its technological advancement and environmental friendliness.

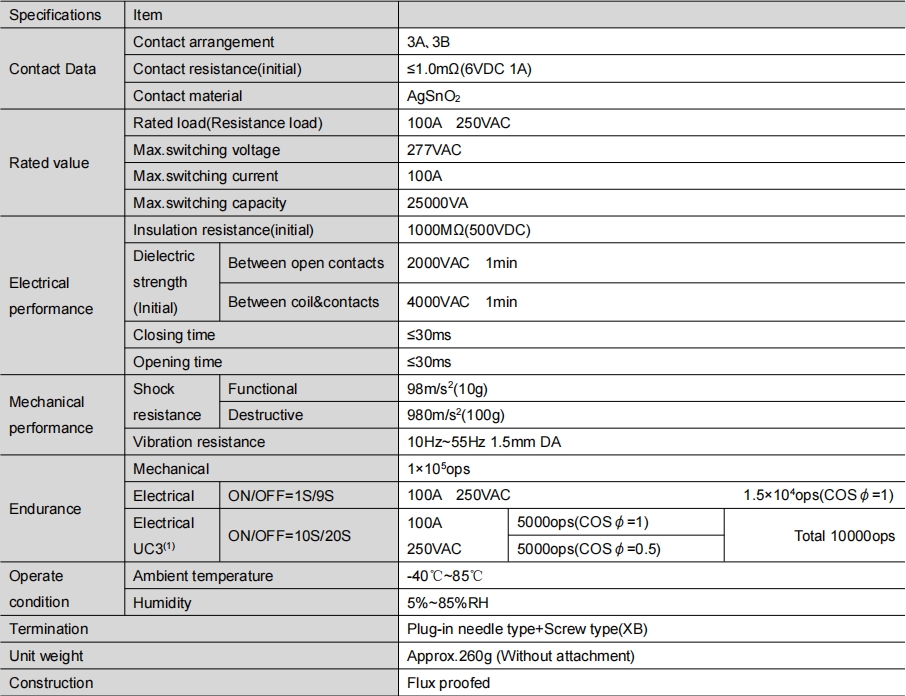

In high-energy scenarios such as smart meters, the FH29L's 100A rated current and 277VAC maximum switching voltage can easily cope with extreme load demands. Its 25,000VA switching capacity ensures stable operation in high-power environments and avoids the risk of failure caused by current fluctuations.

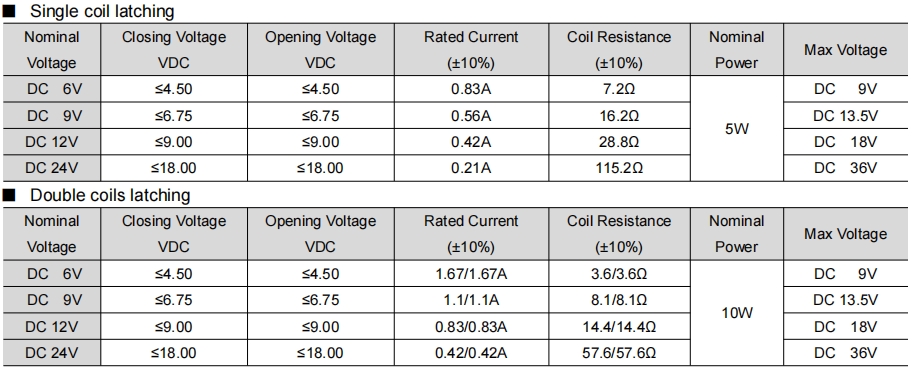

Users can choose single-coil or dual-coil blocking design according to actual needs, the former simplifies the control logic, the latter enhances operational redundancy. In addition, external manganese-copper shunts, transformers and other accessories are supported to provide customized solutions for complex scenarios.

Adopting AgSnO₂ (silver tin oxide) contact material, the initial value of contact resistance is as low as 1.0mΩ, with excellent arc resistance. The mechanical life is up to 100,000 operations, and the electrical life has passed the stringent IEC62055-31 test, so it remains stable even in frequent switching scenarios.

The operating temperature range covers -40℃ to 85℃, anti-vibration (10Hz~55Hz) and anti-shock (980m/s²) design ensures stable operation in harsh industrial environments. 4KV voltage resistance between contacts and coils, as well as 1,000MΩ insulation resistance (500VDC), further protects the safety of equipment.

Rated load: 100A 250VAC (resistive load), maximum switching current 100A.

Response speed: Closing and disconnecting action time ≤ 30ms, to meet the needs of rapid control.

Coil options: DC 6V/9V/12V/24V voltage specifications, single coil rated power 5W, dual coil 10W.

Installation compatibility: Supports a mix of pin and screw terminal (XB) connections, suitable for a variety of PCB layouts.

Smart meters: Accurately manage circuit on/off and optimize energy distribution.

Industrial equipment: Remote switching of motors and transformers, supporting instantaneous switching of high currents.

Energy distribution system: realize “one in, two out” symmetrical control scheme, synchronous management of multiple loads.

Customized expansion: Adapt to new energy sources, energy storage and other emerging fields through external sensors or shunts.

The FH29L offers highly flexible configuration options, and users should specify the following parameters:

Contact type: 3A for 3 sets of normally open contacts, 3B for 3 sets of normally closed contacts.

Coil mode: L1 (single coil) or L2 (dual coil), the latter supports redundant control.

Driving voltage: from DC 6V to 24V selectable, supports reverse polarity (R marking).

Special Requirements: For example, customized PCB mounting (standard or customer-specified) with exclusive code marking.

Initial state calibration: The product is factory defaulted to closed state, but due to transportation vibration may lead to contact offset, manual reset is required before use.

Voltage optimisation for driving: It is advisable to energise the coil with 1 to 1.5 times the rated voltage and a pulse width of at least 100 ms, while avoiding concurrent activation of twin coils or prolonged excitation.

Welding process limitation: Load terminals are not suitable for reflow or wave soldering, spot welding process is recommended to reduce mechanical stress.

Environmental protection: Avoid external impact or high temperature and high humidity environment, regularly check the contact status to prolong the service life.