A shunt is an accuracy low-resistivity resistor that is used to measure or distribute current in a circuit. Shunts in relays and associated electrical systems are commonly wired in parallel to both terminals of the load or coil using Ohm's law (U=I-R) to translate the current signal to a measurable signal of voltage to enable current monitoring, protection, or energy control.

Current Detection: Calculate the value of current flowing through the circuit by measuring the small voltage drop across the shunt.

Current distribution: In parallel circuits, the shunt can regulate the current distribution in different branches to avoid overload.

Energy Drain: In the event of a relay coil being de-energised, the shunt absorbs the reverse electromotive force to protect the switching contacts.

Shunts are usually made of highly stable alloys such as Manganin or Constantan, which have:

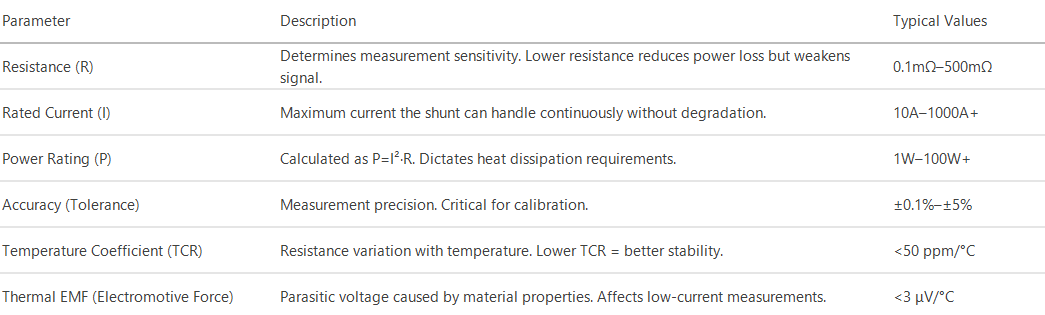

Extremely low temperature coefficients (TCR <50 ppm/°C), which ensures a small variation of the resistance value with temperature.

High tolerance to withstand high current for extended periods of time without burning out.

Low thermal potential to minimize measurement errors.

Ideal for accurate measurements of small currents (<10A), such as electronic protection circuitry.

Metal Bar Type (Bar Type): For medium currents (10A~100A), such as power management.

Bolt-On: for high currents (100A~1000A+), e.g. industrial relays, electric vehicle battery monitoring.

Relay coils generate a reverse induced voltage (reverse electromotive force) when the power is cut off, which may damage the driving circuit (e.g. transistors or MOSFETs). A shunt connected in parallel across the coil provides a low impedance path to absorb the transient energy and protect the switching elements.

Common application examples:

In automobile relays, shunts suppress voltage spiking when the coil is turned off in order to avoid damage to the ECU.

In industrial control systems, current-continuing diodes are coupled with shunts to provide extended relay life.

High-load motors as well as heaters are controlled by using relays in most cases, while the use of shunts to check current regularly prevents overloading.

Workflow:

1. The shunt is connected in series with the load circuit, and when current passes through it, a minor voltage drop is produced (for example, a 50A current passing through a 1mΩ shunt produces a 50mV voltage).

2. An analog-to-digital converter (ADC) or comparator receives this voltage signal and compares it to a predetermined threshold.

3. The relay initiates a protective action (such as an alarm or circuit cut-off) if the current surpasses the limit.

Typical Applications:

Motor Protection: Monitor motor running current to prevent blocking or overload burnout.

Power management: In UPS or inverters, shunts are used to accurately measure battery charging and discharging currents.

In high power use cases, numerous relays can be paralleled to provide higher current-carrying capability. Because of variations in the manufacturing process, each relay's internal resistance can be different, making current distribution uneven (some relays can be overloaded). A shunt can be utilized to dynamically redistribute current to balance each relay's operation.

A shunt is connected in series in each relay branch to monitor the current in each branch.

The control circuit (e.g. PWM regulation) dynamically adjusts the on-time of each relay to equalise the current.

Current range: select the shunt with rated current ≥ 1.2 times the actual maximum current.

Resistance value selection:

- High current (>100A): select a resistance range of 0.1mΩ to 1mΩ to minimize heat generation.

- For low current applications (less than 10A), select a resistance range of 10mΩ to 100mΩ to enhance measurement resolution.

Heat dissipation design: a high current shunt requires compatibility with a heat sink or the implementation of forced air cooling.

Mounting method:

- Small current: PCB mounting (e.g. 2512 package).

- High current: bolt on (e.g. copper shunt).

Cause: Contact resistance, temperature drift or noise interference.

Solution:

- Use four-wire system (Kelvin connection) to eliminate the effect of lead resistance.

- Select low temperature drift materials (such as manganese copper).

- Increase the filter circuit (such as RC low-pass filter).

Cause: Insufficient thermal dissipation or an overcurrent limit.

Resolution:

- Determine whether the actual current exceeds the rated value.

- Optimise heat dissipation (e.g. install heat sinks or change to a larger shunt size).

Cause: Voltage fluctuation due to high-frequency switching (e.g. PWM).

Solution:

- Add beads or common mode chokes to the shunt output.

- Use differential amplification circuit to suppress common mode noise.

Intelligent shunt: Integrated current sensor, ADC and digital interface (e.g. I²C), direct output of digital signals.

Wide temperature range applications: high stability shunt for extreme environments (e.g. -40°C~150°C).

Optimised for high-frequency applications: low inductance shunts for switching power supplies (100kHz+).

Shunts play a key role in relay systems for current monitoring, protection and energy management. Correct selection and application can significantly improve the reliability, accuracy and safety of the system. With the development of power electronics technology, the shunt is moving towards the direction of high-precision, intelligent, high-temperature resistance, and will play a greater role in the future in the new energy, industrial automation and other fields.