A reverse power relay is a directional protection device intended to avert the backflow of current or power to a generator or its prime mover within a power system. It is typically employed in scenarios involving multiple power sources, such as parallel operation of multiple generators or parallel connection of generators to a common busbar/utility grid. Its fundamental function is to trip and disconnect the generator when its output drops below a preset threshold, triggering reverse power flow (i.e., the generator ceases supplying power and instead draws energy from the system, operating like a motor). This prevents damage to the generator.

Failure to disconnect may result in:

The generator rotor is driven, which creates a mechanical load on the primary mover.

Safety threats (fire/explosion risks) associated with the primary mover (e.g., diesel engine or steam turbine) resulting from unburned fuel.

Blackouts or black starts in the power system may be caused by overloading or stability issues in parallel power sources.

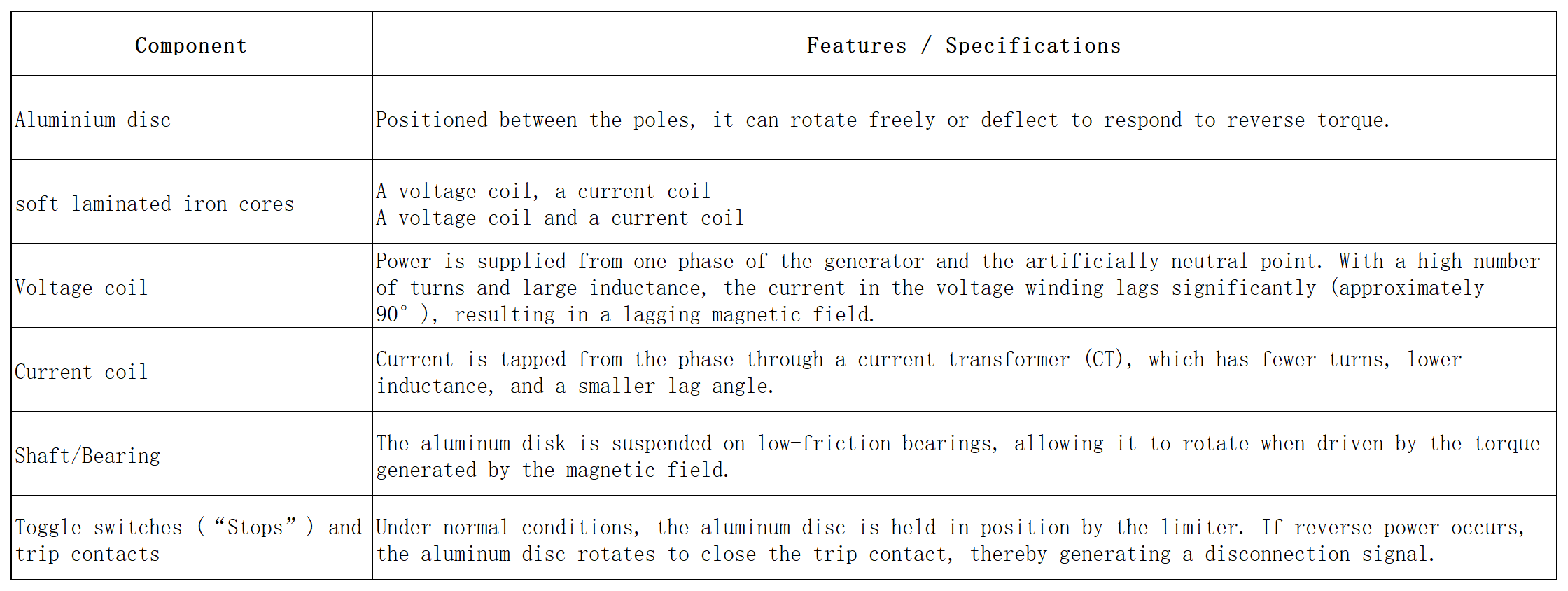

Traditional inverter power relays employ an electromagnetic/electromechanical structure, primarily comprising:

The generator normally outputs power to the busbar. The direction and phase of the magnetic field generated by the voltage coil and current coil cause the torque applied to the aluminum disk to be zero or fixed by the limiter. The trip contacts are open; the relay does not operate.

When generator output power decreases—e.g., due to insufficient host torque supply, governor failure, grid frequency/synchronization issues—power may flow back from the busbar to the generator, causing the generator to be “driven” by other power sources.

The phase difference between the current and voltage coils, along with magnetic field interaction, generates a torque on the aluminium disc that operates in the opposite direction. The aluminium disc commences anticlockwise rotation, receding from the limit position. In the end, this ends the encounters. This activates the relay to emit an action signal. The generator is also disconnected from the system.

In order to circumvent erroneous triggering during transient fluctuations (e.g. minor disturbances during synchronisation), reverse-power relays characteristically incorporate adjustable trigger settings (ordinarily a percentage of the generator's rated current) and time delays.

The trip point is often established within the 2-20% range. For diesel engines, it is typically 8-15%, while for steam turbines it is lower, such as 2-6%.

Time delays are commonly set to several seconds (e.g., 5 seconds) to prevent false tripping.

In marine electrical systems, parallel generators are commonplace. To reliably ensure power stability for critical loads (such as propulsion, navigation, and communications), it is essential to prevent any generator from being driven in reverse. Failure to promptly disconnect reverse power may cause generator overspeed, mechanical damage to the drive unit, or even instability or power loss in the entire ship's electrical system.

Similar applications exist in power plants, industrial facilities, or standby generator systems connected to utility grids to safeguard generator equipment, protect units, and maintain system stability.

The prompt identification and segregation of reverse power can safeguard generators and their associated drive systems.This prevents damage caused by "motoring" that could be caused by mechanical or thermal stress.

Enhances system stability by preventing individual units from drawing energy from the busbar/other generators in parallel systems or when connected to a common busbar, safeguarding overall power distribution.

It reduces the possibility of an unburned fuel fire or explosion, especially in combustion devices.

Electromechanical relays are bulky and structurally complex, requiring maintenance for mechanical components (aluminum discs, bearings, limiters, etc.).

False tripping or delayed response during frequent load changes or brief reverse pulses can result from improper delay settings.

In the digital control era, electromechanical relays exhibit limitations in response speed and adjustable range flexibility when compared to modern electronic or microprocessor-based protection devices.

During synchronization or parallel switching operations, improper handling may introduce transient reverse conditions or voltage/phase difference issues, requiring careful execution. The quick detection and isolation of reverse power can protect generators and their drive systems.

When selecting inverter power relays or designing related protections in actual engineering projects, the following factors should be considered:

Generator rated voltage, current, frequency, and the maximum possible load and overload conditions of the parallel system.

Set based on unit characteristics: The set is based on unit characteristics. Different drive units, such as diesel engines and steam turbines, exhibit varying sensitivity to reverse power. For example, diesel engines may require a higher percentage to avoid false tripping under light loads or when switching, whereas steam turbines may require a lower percentage.

Ensure that transient instabilities caused by short-term fluctuations or synchronization processes do not trigger false trips, while enabling rapid protection action during actual reverse power flow.

Regularly assess the relay's tripping mechanism (e.g., using simulated reverse power or load shifting evaluations). Inspect electromechanical components (bearings, limiters, etc.) for flexibility and absence of mechanical binding. Web pages mention verification via load shifting or the relay's “boost test” button.

When multiple generators operate in parallel, consider protection coordination (which unit trips first, which remains online) and interaction with other protections (overload, overcurrent, loss-of-excitation, etc.).

While contemporary systems may favour electronic or digital relays and integrated protective devices for their enhanced accuracy, adaptable configurations and remote monitoring and diagnostic functionalities, electromechanical devices still have advantages in terms of reliability and immunity to interference in certain environments .

Critical to the safety of generators, drive units, and the system as a whole, inverter power relays stop electricity from flowing backwards in parallel generator systems. Reverse power detection is achieved through electromechanical structures (aluminum disc, dual electromagnetic coils, limiters/trip contacts). Implementation in practice necessitates meticulous attention to detail when setting the trip percentage and time delay, as well as regular testing, maintenance, and cooperation with other safety systems.