Fanhar made the FH62NE, a high-performance power latching relay, just for the new energy and industrial control sectors. It integrates high load capacity, intelligent safety monitoring, energy-efficient operation, and a long-life design, strictly complying with international electrical standards. It is ideal for applications with demanding requirements for electrical performance, system safety, and environmental resilience.

The FH62NE was designed with the following four goals in mind: "Safety, Reliability, Efficiency, and Compactness":

Safety Redundancy: Features an independent auxiliary contact set with status monitoring capability. This provides critical safety feedback for the main load circuit, fulfilling a safety monitoring function as per IEC 61810-3, especially in case of main contact welding.

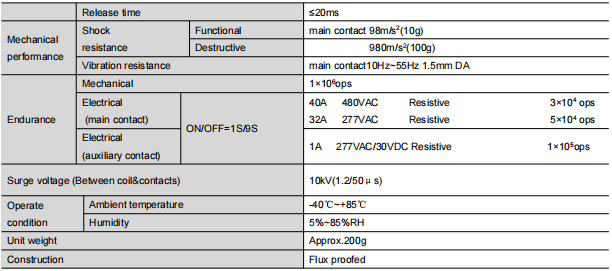

Energy Efficiency Optimization: Employs a low-power latching coil design (rated power: 4.8W). After the operation, applying a reduced sustaining voltage can maintain the state, which significantly lowers long-term system energy loss and heat generation.

Environmental Ruggedness: Reliable performance in harsh outdoor and industrial environments is ensured by a fully sealed, flux-proofed construction, combined with a wide operating temperature range (-40°C to +85°C) and humidity range (5% to 85% RH).

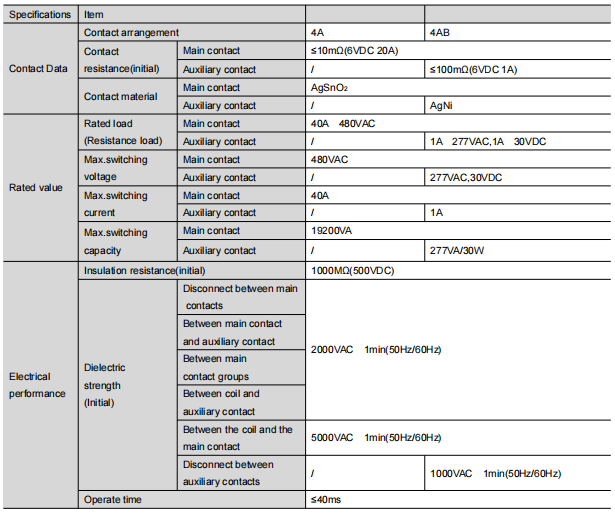

Main Contacts: 4 sets of contacts.

Contact Material: AgSnO₂.

Rated Load: 40A @ 480VAC (Resistive).

Maximum Switching Capacity: 19,200 VA.

Initial Contact Resistance: ≤ 10 mΩ.

Electrical Endurance: 3 x 10⁴ operations at 40A / 480VAC resistive load (ON/OFF cycle: 1s/9s).

Auxiliary Contact: 1 set.

Contact Material: AgNi.

Rated Load: 1A @ 277VAC / 1A @ 30VDC.

Safety Function: Ensures a minimum separation of ≥0.5mm in the event of main contact adhesion, facilitating fault indication.

Insulation System: UL Class F.

Creepage Distance: >8mm.

Dielectric Strength (Initial):

Between main contacts, contact groups, and main/auxiliary contacts: 2000 VAC for 1 min.

Between coil and contacts: 5000 VAC for 1 min.

Surge Withstand: 10 kV (1.2/50 µs) between coil and contacts.

Coil Power: 4.8W.

Voltage Options: DC 6V, 9V, 12V, 24V, 48V.

Sustaining Voltage: Can be reduced to 40%-100% of nominal voltage at 25°C (50%-60% at 85°C) after operation for power saving.

Operate Time: ≤ 40ms.

Insulation Resistance: ≥ 1000 MΩ at 500VDC initially.

Mechanical Life: 1 x 10⁶ operations.

Shock Resistance: Functional: 98 m/s² (10g); Destructive: 980 m/s² (100g).

Vibration Resistance: 10Hz-55Hz, 1.5mm double amplitude for main contacts.

Compact Dimensions: 58mm x 35mm x 47mm. Weight: ~200g.

The device is engineered to comply with and is now seeking approvals for UL/C-UL, TUV, and CQC standards, with the following ratings:

Main Contact: 50A/277VAC (no damage), 32A/277VAC (5x10⁴ ops).

Auxiliary Contact: 1A/30VDC & 1A/277VAC (1x10⁵ ops).

Solar Photovoltaic Inverters: Designed for load switching and isolation, able to endure pertinent voltage transients.

AC Charging Spots (EV): As a key switching component in charging control circuits, offering high-current handling and safety monitoring.

Industrial Control & Power Distribution: Great endurance and reliability make it suitable for motor control, power switching and similar applications.

Safety-Critical Systems: The auxiliary contact offers essential status information for monitoring functional safety.

Mounting: PCB mount recommended. Consult the specification for detailed dimensions and layout (tolerance parameters included).

Soldering: For copper load terminals: 260°C ±5°C for 3-5 seconds.

Voltage Application: To prevent the coil from overheating, do not consistently exceed the maximum sustained voltage.

Handling: Avoid dropping or subjecting the relay to excessive force to maintain initial performance.

With its sturdy construction, high-current capabilities, integrated safety measures, and energy efficiency, the FH62NE New Energy Relay is ideal for new energy generation, electric car infrastructure, and demanding industrial applications. Zhejiang Fanhar Electronics is dedicated to providing reliable, high-quality components by continuously innovating and maintaining strict quality control.