In modern industrial and commercial power systems, three-phase alternating current is the core driving force powering the world. From factory motors and compressors to the central air conditioning in large buildings, their stable operation relies on the protection of a key component—the Three-Phase Control Relay. This article will provide a comprehensive analysis of this device, covering everything from its fundamental definition to its intelligent applications. It will explain why it is considered the 'intelligent guardian' of industrial power systems.

A three-phase control relay, also known as a "contactor" when it comes to driving high-power loads, is an electrically operated switching device that is specially designed for making, breaking and controlling three-phase AC loads. Its core value lies in its ability to safely control the switching of a much higher-power three-phase main power circuit (e.g. 380 V AC or higher) using a low-power control signal circuit (e.g. 24 V DC or 110 V AC). This design achieves "controlling the large with the small, and the strong with the weak," fundamentally isolating operators from the dangerous high-voltage main circuit.

The key distinction from a standard relay lies in its current-carrying capacity and design purpose. Standard relays are typically used in control circuits or for small single-phase loads, whereas the contacts, arc suppression systems, and mechanical structure of a three-phase control relay are reinforced for three-phase balanced loads, high inrush currents during start/stop, and frequent operation. It is essentially the critical execution interface between automation systems and the main power system, providing a standardized, reliable connection point for integration with PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), soft starters, or energy management systems.

The necessity of deploying three-phase control relays stems from the stringent demands of industrial environments for safety, reliability, and efficiency.

Essential Safety Barrier: It provides a vital safety barrier for operating and maintenance personnel. Engineers can remotely control high-voltage, high-power equipment on the factory floor from dozens of meters away, within the safety of a low-voltage control room, via pushbuttons or an HMI (Human-Machine Interface), greatly reducing the risks associated with directly operating high-voltage switchgear.

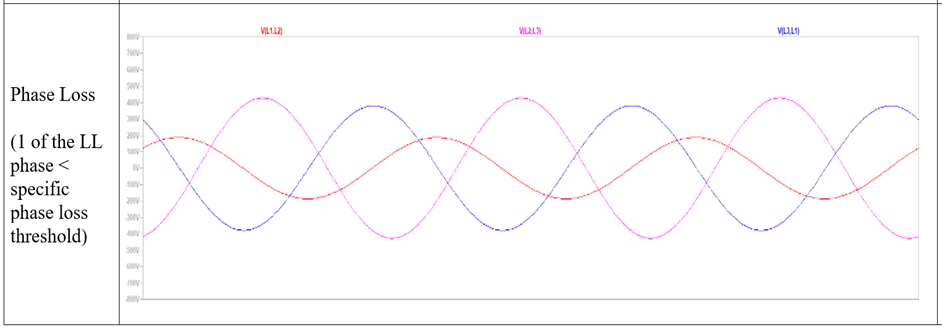

Critical Asset Protection: Motors and other rotating equipment are core industrial assets. Their most fatal "killers" are often phase loss, imbalance, overload, and undervoltage. Control relays work in tandem with independent thermal-magnetic protection units or electronic overload relays to form a dual-layer protection scheme. For example, a phase loss condition can cause the current in the remaining two phases of a running motor to surge. This surge can be as high as 1.73 times normal. This can lead to rapid overheating and burnout. Severe voltage imbalance generates negative sequence currents. These currents cause additional heating and vibration. However, the relay can detect and interrupt the circuit within tens of milliseconds, thus preventing catastrophic damage.

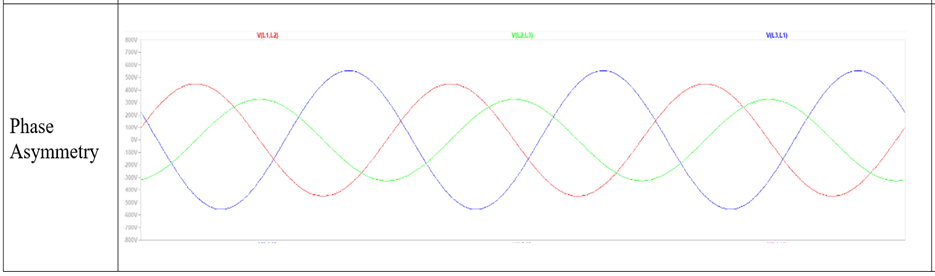

Foundation for Operational Continuity and Energy Efficiency: Unplanned downtime represents a significant loss in industrial production. Through preventive protection, relays avoid production halts and repairs lasting days or even weeks caused by motor burnout. They also ensure that the equipment operates under rated voltage and balanced conditions. Studies show that a long-term voltage imbalance of 3.5% can raise motor temperature by 25%, reduce efficiency, and increase power usage. By monitoring and providing alarms, relays prompt users to improve grid quality, directly saving energy costs.

Physical Enabler for Automation and Intelligence: It is the elementary "unit" forming the basis of all contemporary automation logic. Whether it is implementing a star-delta start-up for a motor, a sequential start/stop for multiple devices or responding to temperature/humidity signals from a building management system, the final execution relies on the reliable opening and closing of a three-phase control relay.

The latest three-phase control relays are much more than just simple switching units. They are now able to monitor and diagnose power quality online as part of their integrated functions. They continuously "listen" to and analyze the "health status" of the three-phase supply.

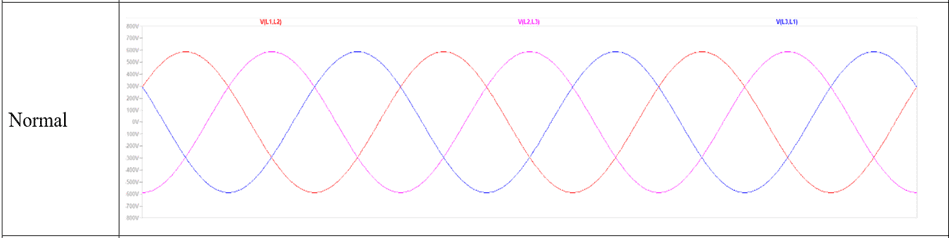

Figure 1 Ideal Three-phase Power Network

Phase Loss: Caused by fuse blowing, contactor contact welding/failure, broken wires, or loose connections.

Incorrect Phase Sequence: Equipment with rotation direction requirements, such as pumps and fans, is susceptible to mechanical reversal or even damage if the phase sequence is incorrect.

Voltage Imbalance: This is caused by uneven single-phase load distribution. It is also caused by grid issues. And it is caused by asymmetric impedance. A voltage imbalance exceeding 2% typically requires attention.

Overvoltage and Undervoltage: Voltage fluctuations beyond equipment tolerance can damage insulation or cause insufficient torque and overheating.

Figure 2 Three-phase power network with one-phase loss

Based on functional depth, monitoring relays can be categorized as:

Basic Type: Monitors phase loss and phase sequence.

Standard Type: Adds basic monitoring for voltage imbalance, over/undervoltage.

Enhanced/Intelligent Type: Offers programmable thresholds, time delays, asymmetry calculations, and may integrate current monitoring, power measurement, and even data upload via communication interfaces.

Figure 3 Three-phase power network with phase asymmetry

When any parameter exceeds the preset safety threshold, the relay's internal logic circuit drives the output contacts to change state. This is usually employed to interrupt the control circuit of the main contactor, thereby stopping the equipment. It may also use an additional set of auxiliary contacts to trigger audible or visual alarms.

It works on the same basic idea as classical electromagnetism, but modern designs use many improvements in materials and mechanical engineering.

Energization and Force Generation: When control voltage is applied to the coil, the generated magnetic field magnetizes the stationary core, attracting the moving core (armature). The coil's insulation material and winding design ensure long-term heat resistance and accurate pickup voltage.

Mechanical Transmission and Contact Closure: The armature's movement is transmitted via a mechanical linkage to the main and auxiliary contacts. The main contacts usually consist of silver-based alloys (e.g. silver-cadmium oxide or silver-tin oxide), which offer good conductivity and resistance to arc erosion and low contact resistance. During the instant of contact closure, built-in contact pressure springs ensure initial contact pressure, reducing bounce and welding risk.

Arc Management and Breaking: Breaking high currents generates high-temperature arcs. Relays use arc chute technology with metal grids to split, cool and elongate the arc for rapid extinguishing.This is key to ensuring contact life and safe breaking capability.

Release and Reset: Once the control signal has disappeared, the coil demagnetises. The return spring, which is typically stronger than the contact spring, then rapidly pushes the armature back to its original position. The contacts separate as quickly as possible to minimise arcing time.

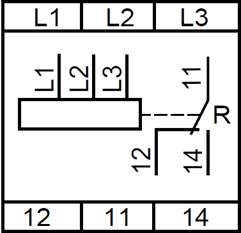

Figure 4 Typical wiring diagram of a three-phase control relay

A typical three-phase control relay consists of the following precision subsystems:

Electromagnetic System: Includes the bobbin, coil, stationary core made from laminated E or U-shaped silicon steel sheets, and the moving core. The design of silicon steel sheets, which is characterised by high permeability and low eddy current loss, ensures high efficiency, low energy consumption and low heat generation.

Main Contacts: There are three pairs carrying the main circuit current, which have a large area and high material requirements.

Auxiliary Contacts: For control circuits, usually modular plug-in designs for flexible configuration, providing Normally Open (NO) and Normally Closed (NC) signals.

Arc Suppression System: Mostly consists of an arc hood made of ceramic or high-strength plastic and an internal set of copper-plated steel splitter plates.

Mechanism and Enclosure: High-strength engineering plastic or thermoset housing providing insulation, protection (IP rating), and mechanical support.

Determine Load Characteristics: Identify if the load is a motor, resistance furnace, or transformer? Key parameters include the motor's starting current (typically 5–7 times the rated current) and duty cycle (e.g. S1 for continuous duty or S3 for intermittent periodic duty).

Coil Voltage: Must exactly match the control supply voltage (AC/DC, value).

Rated Operational Current (Ie): The voltage at which the main contacts can carry current is specified. It must be greater than the load's full load current (FLC). For motor loads, consider the thermal shock during starting and allow a margin of 10–15%.

Rated Insulation Voltage (Ui) and Impulse Withstand Voltage (Uimp): Must match the grid level.

Utilization Category: AC-3 (squirrel cage motor starting/stopping) or AC-1 (resistive load) are most common. AC-3 category requires higher breaking capacity.

Monitoring Needs: Is voltage monitoring required? Are adjustable thresholds and delays needed? Is fault memory and indication needed?

Electrical Life and Mechanical Life: Refers to the number of reliable operations under rated conditions. Check the mounting method (DIN rail or screw), the required number of auxiliary contacts and whether a mechanical interlock or timer/communication modules are needed for reversible control.

Confirm Installation and Accessories: Check the mounting method. This could be DIN rail or screw. Also check the required number of auxiliary contacts. And whether a mechanical interlock or timer/communication modules are needed for reversible control.

Environmental Suitability: Consider ambient temperature. Consider humidity. Consider dust. Consider corrosive gases. Consider vibration. Select the appropriate protection rating (IP code). Select the appropriate material/process.

The three-phase control relay is a versatile foundational component, with applications spanning:

Manufacturing: Machine tools, conveyors, injection molding machines and compressors all require motor control.

Infrastructure: Pumps, fans, air handling units, lighting distribution cabinets.

New Energy: Cabinets that conform to the grid-tie standard are used for photovoltaic inverters, and power module control is used for charging stations.

Building Automation: Automatic control for domestic water pumps, fire pumps, ventilation equipment.

Condition Monitoring and Predictive Maintenance: Next-generation relays will integrate more advanced sensors capable of monitoring contact erosion, temperature rise, coil health, and use algorithms to predict remaining useful life, enabling a shift from "scheduled replacement" to "on-demand maintenance."

Deep Integration into the Industrial IoT: By integrating industrial Ethernet protocols like Profinet, EtherCAT, Modbus TCP, etc., relays will become intelligent nodes in the IIoT network, uploading real-time data on current, voltage, power consumption, status, and alarm information, providing foundational data for digital twins and energy management.

Functional Safety Integration: Integrating safety functions compliant with standards like IEC 61508 or ISO 13849, such as Safe Torque Off (STO), allows direct use in building safety control systems, simplifying safety loop design.

Device Fusion and Miniaturization: Functions will further integrate with those of variable frequency drives, soft starters, and protection devices, forming intelligent motor controllers that combine control, protection, speed regulation, and diagnostics, while power density continuously increases.

The three-phase control relay has evolved from a simple electromechanical switch into a key intelligent device integrating power monitoring, equipment protection, logic execution, and data acquisition. It is the stable cornerstone of the industrial automation pyramid and a bridge connecting the physical power world with the digital information world. A deep understanding of its principles, value, and selection methods is essential not only for ensuring the reliable operation of individual devices but also for building safe, efficient, flexible, and future-oriented modern industrial power systems. Its role will become increasingly vital in the context of Industry 4.0 and dual carbon goals.