Relays are an indispensable core component in modern electrical control systems. Latching relays and non-latching relays are used in very different scenarios due to their different functional characteristics. In this article, we will analyse the differences between the two from the working principle, performance comparison, application areas and other perspectives, and guide how to choose the most suitable type according to the needs.

Self-latching relays are triggered by electromagnetic pulse and can maintain the contact state without continuous power supply. The internal mechanical latching or magnetic latching mechanism is used to achieve the ‘Bistable’ characteristic. For example, the magnetic self-locking type maintains contact position by means of permanent magnets, whereas the mechanical type relies on a ratchet structure to hold the state.

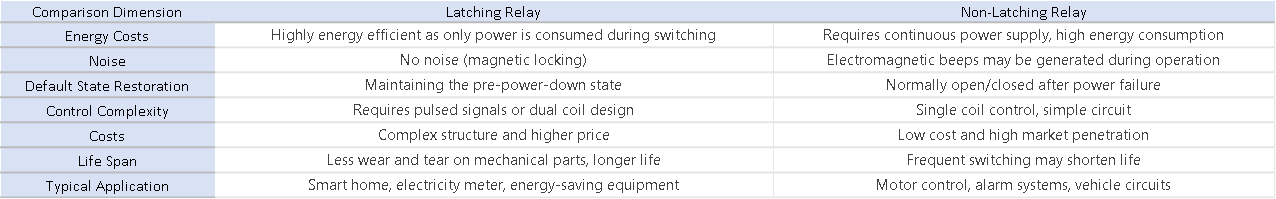

Pulsed operation: Only a short current is required to switch states, and power consumption is extremely low.

State memory: the last operation state is maintained after power failure, suitable for the scenarios that require long-lasting control.

Non-Latching Relay changes the contact state when power is applied and restores the default position (normally open or normally closed) immediately after power is removed. It relies on a continuous current to maintain closure and is suitable for scenarios that require frequent switching or temporary control.

Continuous Power Requirement: The coil needs to be energised for a long time to maintain its state, with high energy consumption.

Simple control: simple structural design, low cost.

Advantageous areas of self-locking relays

Energy-saving devices: such as smart meters, remote control systems, relying on its low power consumption characteristics.

State memory requirements:

Lighting control: multi-position switches (e.g. staircase lights) switching by single pulse without continuous power supply.

Battery-powered devices: portable medical equipment, RV motorhome battery management to avoid power waste.

Industrial automation: for safety interlock systems, HVAC temperature control to ensure no loss of status after power failure.

Applicable scenarios for non-self-locking relays

Frequent switching requirements:

Motor control: industrial pumps, fans start and stop need fast response.

Vehicle circuits: lights, wipers, and other short-term operating devices.

Low-cost solutions: home appliances, basic electronic equipment in the priority.

Energy priority: If the system needs to run for a long time and is sensitive to power consumption (e.g. solar equipment), self-locking relays are preferred.

Control complexity: self-locking type needs to be designed with pulse circuits or dual coil drive, suitable for projects with technical reserves; non-self-locking type is suitable for simple switching needs.

Environmental noise limitations: medical equipment, home scenarios, self-locking type of silent characteristics are more advantageous.

Budget constraints: the price of non-self-locking type is only 1/3 of self-locking type (e.g. 1.5vs1.5vs4.5), which is suitable for cost-sensitive projects.

The choice between self-locking and non-self-locking relays is essentially a trade-off between power consumption and cost. The former is known for its high energy efficiency and long-lasting status, while the latter is known for its simplicity and economy. In the smart home, industrial automation and other high-end scenarios, self-locking is gradually becoming the mainstream; while the traditional manufacturing industry, basic electronic equipment still rely on non-self-locking cost-effective.