In the fields of industrial automation, power control, and compact equipment design, space optimization and reliability are perpetual pursuits. The FH19 series relay is born to address these core needs. As an ultra-thin PCB relay with a mere 5mm thickness, it successfully integrates high performance, long lifespan, and high-density mounting capability, making it the ideal choice for engineers in space-constrained scenarios. This article will explore the design features, technical benefits, and diverse applications of the FH19, offering thorough selection and application recommendations.

The FH19 measures 20.2×5.2×12.5mm. Its slim profile — particularly its 5 mm thickness — allows for vertical stacking or high-density layouts in a side-by-side configuration, which significantly saves PCB space. Compact applications such as industrial control motherboards, PLC modules, communication devices and smart appliances are the ideal candidates for this optimally designed product.

It utilises a Bifurcated Welded Double Contact configuration. This design utilises two parallel contact points to distribute current, thereby reducing contact resistance and markedly enhancing contact reliability and stability. Even if one contact point is compromised due to micro-vibration or contamination, the other ensures circuit continuity, significantly boosting failure resistance in harsh industrial environments.

Environmental Compliance: The full series complies with the RoHS directive, uses no hazardous substances, and meets global green manufacturing trends.

Contact Material: Utilises a silver-nickel (AgNi) alloy. This preserves silver's outstanding conductivity, while the incorporation of nickel improves arc erosion resistance and mechanical robustness, hence prolonging electrical longevity.

Insulation System: Features a UL Class F (155°C) insulation system, ensuring excellent electrical isolation performance and safety margin even in high-temperature environments.

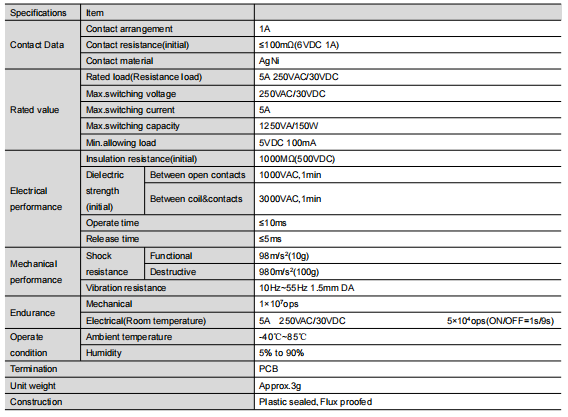

Rated Load: 5A @ 250VAC / 30VDC

Max. Switching Capacity: 1250VA / 150W

Contact Resistance: ≤100mΩ (initial)

Insulation Resistance: ≥1000MΩ (500VDC)

Dielectric Strength: 3000 VAC for 1 minute (between open contacts and between coil and contacts)

Operate/Release Time: ≤10ms / ≤5ms

Mechanical Life: Capable of up to 10 million operations, ideal for frequent toggling.

Electrical Life:The specified load guarantees reliable performance (see the "Endurance Curve" in the datasheet).

Environmental Adaptability: Operating temperature range of -40°C to +85°C and humidity range of 5% to 90%, suitable for various climates.

Vibration & Shock Resistance: Excellent vibration (10-55Hz) and shock (980m/s²) resistance, ideal for equipment with mechanical vibration like machine tools and vehicles.

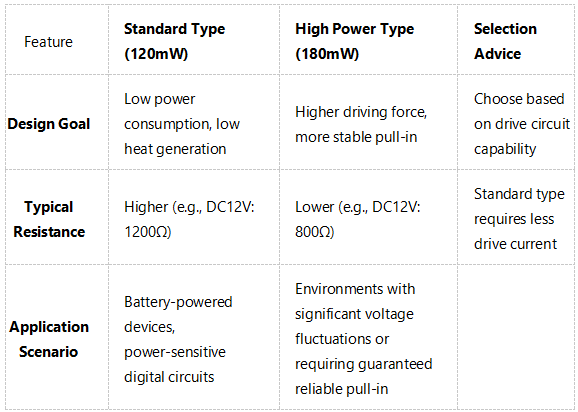

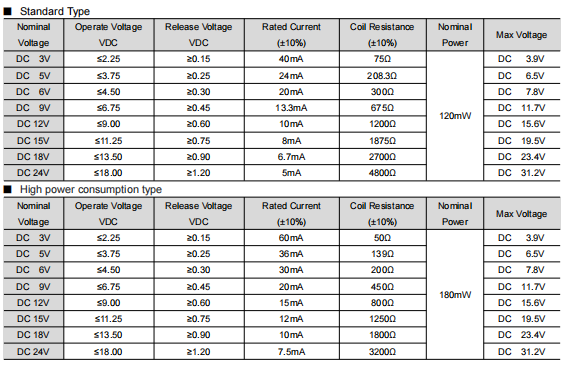

The FH19 has two coil power types. It also has eight common voltages. This affords designers significant versatility.

Important Note: The datasheet specifies the "Operate Voltage" and "Release Voltage" characteristics in detail. The FH19's design, materials and manufacturing process adhere to rigorous safety standards, as indicated by the certifications. Users can safely incorporate it into applications requiring export compliance or exceptional reliability.

The FH19 offers two key package options to address different environmental challenges:

Feature: Resists weakly corrosive residues from soldering.

Recommended for: Maintain hygienic interior settings, including data centre apparatus, communication facilities, and laboratory instruments.

Feature: Fully sealed structure effectively prevents dust, moisture, and corrosive gases (e.g., H₂S, SO₂) from entering the relay.

Recommended for: Industrial sites, outdoor equipment, environments with chemical gases, such as factory workshops, control cabinets, traffic signal systems, and agricultural machinery.

Selecting an inappropriate package may result in interior corrosion, contact oxidation, and premature failure.

Leveraging its comprehensive advantages, the FH19 excels in the following fields:

Industrial Automation: PLC I/O modules, sensor interfacing, small motor control.

Energy Management: Smart meters, photovoltaic inverter control circuits, and charging station control modules.

Building Automation: Intelligent lighting control, HVAC system control, security systems.

Communication Equipment: Signal routing in network switches, routers, and base station apparatus.

Home Appliance & Consumer Electronics: Control boards for high-end appliances, smart home hubs.

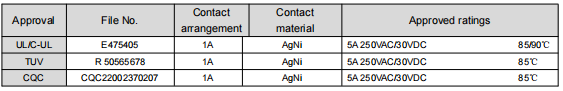

The FH19 has acquired numerous prestigious worldwide and domestic certifications, which serve as the foremost validation of its superior quality and safety.

UL / C-UL (USA/Canada): File No. E475405

TÜV (Germany): File No. R 50565678

CQC (China): Certificate No. CQC22002370207

The certifications indicate that the FH19's design, materials, and manufacturing process adhere to rigorous safety standards. Users can securely include it into applications necessitating export compliance or exceptional reliability.

Determine the Load: Identify your load type (resistive, inductive, lamp), current, and voltage to ensure they are within the FH19's rated range.

Select the Coil: Select the Standard or High Power variant and the appropriate voltage specification according to your system's supply voltage and power demands.

Determine the Package: The choice between Flux Proofed or Plastic Sealed should be made based on the application environment. This is essential for ensuring long-term reliability.

Confirm Pinout: Refer to the PCB footprint diagram (1A1 or 1A2) to ensure compatibility with your circuit board layout.

Design the Drive Circuit: Ensure that a stable and sufficient drive current is provided for the relay coil. Consider using a flyback diode to protect the driving device.

The FH19 is an engineered solution that is designed to address the challenges posed by modern, high-density, high-reliability electronic design.

It integrates compact size, dual-contact reliability, environmental adaptability, and extensive certifications, providing engineers with solid and reliable underlying component support for innovation in industrial control, energy management, and smart devices.

When selecting a relay, go beyond simple parameter comparisons. In terms of system reliability, lifecycle cost and environmental suitability, the FH19 is undoubtedly the preferred option and worthy of in-depth evaluation.